We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

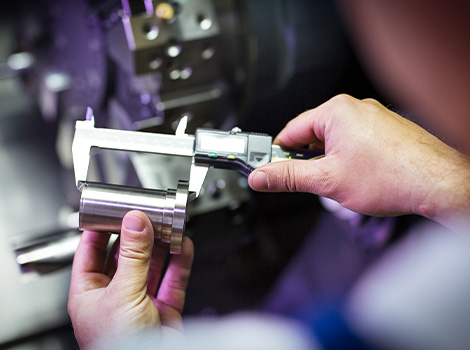

Our temperature-controlled QC room is equipped with cutting-edge technology and purpose-built infrastructure, standing as a testament to the highest standards. Our dedicated team utilizes top-of-the-line equipment, including the Zeiss Contura CNC Coordinate Measuring Machine (CMM), the Mitutoyo Crysta Plus CMM and an Asimeto Digital Measuring Projector. Unlike some practices, we uphold strict standards by assigning quality control responsibilities to our trained QC staff, ensuring meticulous evaluation of every component.

.png)

The latest version of CMM comes with VAST XT probe head and tactile probes. We use the latest ZEISS Calypso 2023 software, version 7.6.00, in a work area that measures 24 inches in the X-axis, 30 inches in the Y-axis, and 22 inches in the Z-axis. The device is equipped with exceptional scanning technology making it the standard in its class.

.png)

The Mitutoyo has a high accuracy level with a range of 3.0 + 4L/1000 µm. Its measuring range is 400 x 400 x 300mm for XYZ dimensions. It's suitable for use on shop floors, and temperature compensation is optional for 15 to 30°C. Additionally, it has high-precision air bearings, a one-touch air clamp, and fine feed for rapid positioning, as well as a vibration isolation system. The machine comes with MCOSMOS inspection software for added convenience.

.png)

The Asimeto digital projector is a powerful and versatile tool that offers many benefits over traditional projectors. It provides high-quality images with accurate magnification, low contour measuring error under 0.08% deviation. These features make it an ideal choice for inspection and quality control.

PARTNER WITH

We believe that quality control is not just a step in our process, but rather a commitment to ensuring excellence in every product we machine. As your reliable partner for all your machining needs, we will provide you with nothing less than the highest level of quality and service.