We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Anodizing services include clear, black, coloured, hard clear, and hard black finishes. Anodizing not only enhances the appearance of metal surfaces but also provides corrosion resistance and improves wear resistance. Whether you require a sleek, red modern look or a clear durable protection for your components, anodizing deliver exceptional results.

Clear chromate coatings are a highly effective way to protect metal parts from corrosion. These coatings can serve as a base for subsequent paint or powder coat applications, providing enhanced durability and longevity for metal parts. Clear chromate services, you can expect optimal adhesion and compatibility with various finishing techniques. Additionally, the clear coating ensures that the natural appearance of the metal parts is preserved, giving them a sleek and polished look.

Electropolishing is a process that can remove surface imperfections and micro-roughness to provide a smooth and shiny finish. This method offers improved corrosion resistance, which is difficult to achieve via other methods. It is particularly beneficial for industries that require high-quality and hygienic finishes, such as medical, food processing, and pharmaceuticals.

Passivation is a chemical process that eliminates free iron and impurities from the surface of stainless steel, resulting in a passive oxide layer that enhances the material's corrosion resistance. This treatment guarantees that your stainless-steel components will endure tough conditions, maintain their structural integrity, and preserve their aesthetic appeal over time.

Black oxide coatings are a cost-effective way to give metal parts a decorative black finish. This coating process reduces light reflection, improves lubricity, and prevents galling of the parts. It is widely used for decorative purposes and in the manufacturing of gears, firearms, fasteners, tools, and fixtures. However, black oxide coatings should not be used for parts that require corrosion resistance.

Electroless nickel plating is a chemical process that uniformly deposits a layer of nickel-phosphorus alloy on a surface. This process is ideal for a variety of applications, including automotive, aerospace, and electronics, as it provides excellent corrosion resistance. Electroless nickel plating results in durable and high-quality finishes that improve both the functionality and aesthetics of metal components.

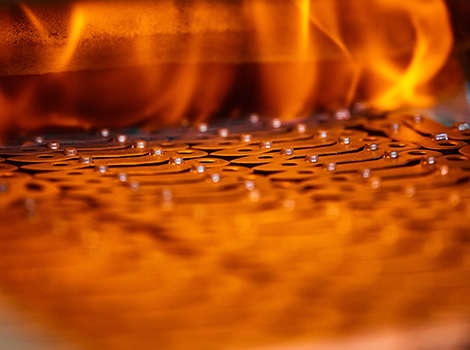

Heat treatment services involve different processes such as annealing, quenching, tempering, and case hardening. These processes are used to improve the mechanical properties of metal components. Heat treatment can help you increase hardness, improve toughness, or enhance machinability of metal parts. It ensures that your parts have the desired metallurgical properties.

PARTNER WITH

When it comes to comprehensive finishing service, Progressive Machining is your trusted partner. With advanced machinery, custom solutions, strict quality control, and a commitment to customer satisfaction, we deliver superior results that exceed expectations.